On 31 December 2016, a particularly exciting and successful year for Ring Alliance is coming to an end.

In spring, Bensons International Systems was integrated into Ring Alliance Ringbuchtechnik and thus, the strengths of these companies were combined even more effectively. This step is of great advantage to you as our customer, especially through our expanded product portfolio. Since then, we are not only your reliable partner for ring binder mechanisms, but we also gladly provide you with accessories for your binders and presentation products.

2016 was thus not only a year of major changes in our company structure, but also a successful business year. We had a very good order situation, particularly in the first half year and our production location in Hungary has been used at full capacity. For the production of your high-quality ring binder mechanisms, we also invested in additional personnel.

We would like to thank you, our valued customer, for the successful year 2016 and the good, trusting cooperation and we look forward to continuing it 2017 with certainly many exciting challenges.

Special thanks to our colleague, Mr. Zwiers:

Andre Zwiers has played a leading role in the successful development of Bensons International Systems for over 30 years and is still making an important contribution to our company as our external consultant. His presence with our customers, his popularity in the industry and his solution-oriented style of work have made a big contribution to the success of our company.

Dear Andre, we sincerely thank you for your extraordinary commitment, your loyalty and reliability, and wish you all the best for your future!

For 26 years, Jürgen Richter has, with his positive attitude, not only accompanied, but also shaped the development of our company as well as of our industry – as a sales agent, initially for Koloman Handler, and later, after the merger with Krause, for RING ALLIANCE.

For 26 years, Jürgen Richter has, with his positive attitude, not only accompanied, but also shaped the development of our company as well as of our industry – as a sales agent, initially for Koloman Handler, and later, after the merger with Krause, for RING ALLIANCE.

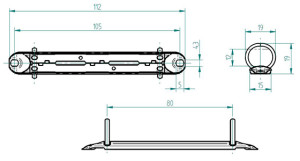

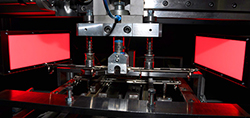

At the machine for the types SXR 272/04/16 und 20(15), there has recently been installed a camera system for quality assurance. The camera, which works in the dark by using red light, registers differences in side and height offsets smaller than 0.1 millimeter.

At the machine for the types SXR 272/04/16 und 20(15), there has recently been installed a camera system for quality assurance. The camera, which works in the dark by using red light, registers differences in side and height offsets smaller than 0.1 millimeter. With the help of two investments, RING ALLIANCE increases the energy efficiency in its manufacturing.

With the help of two investments, RING ALLIANCE increases the energy efficiency in its manufacturing.